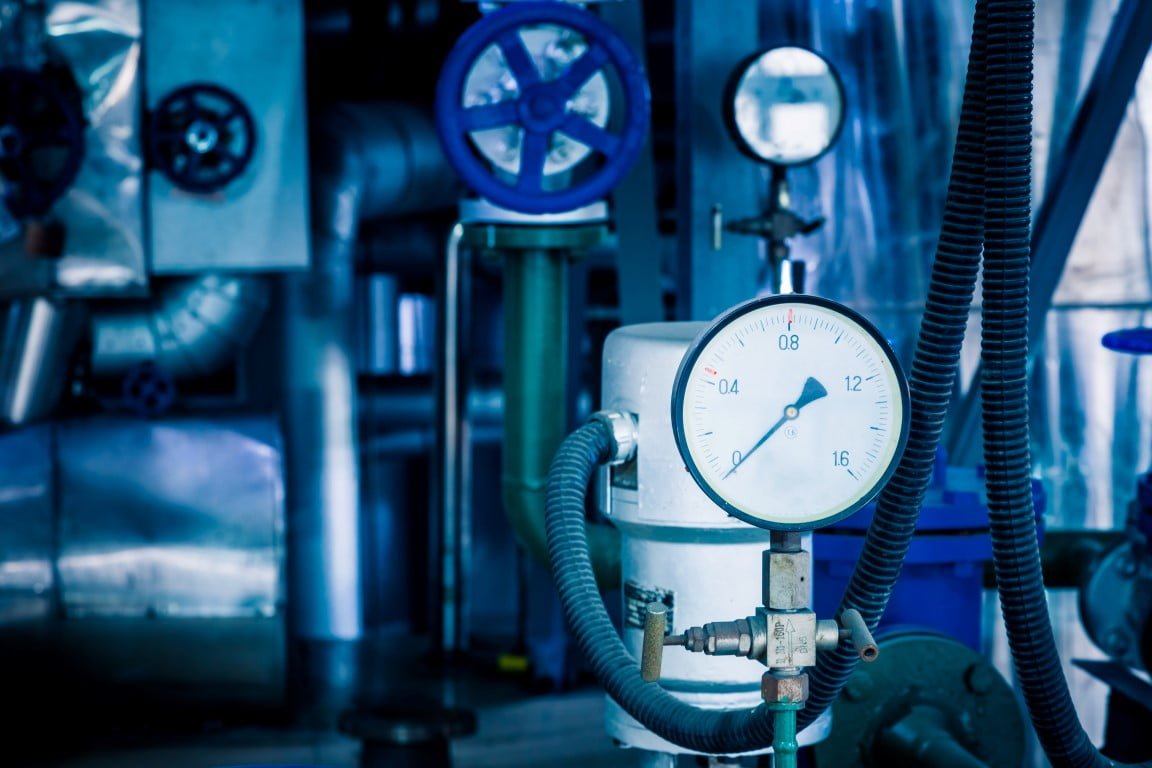

In the world of industrial steam systems, safety and dependability are essential. These systems are utilised in many industries, such as manufacturing and power generation, and they depend on many parts to function as a whole. The boiler header is crucial in guaranteeing the secure functioning of steam systems. Understanding the significance of boiler headers can provide valuable insights into how they contribute to steam system safety and reliability.

What is a Boiler Header?

An essential component of steam systems, a boiler header serves as a central manifold for the collection and distribution of steam. These headers are designed to withstand high steam pressure and temperature, ensuring that steam is transported efficiently and safely to various places throughout the system.

Steam headers and feed headers are the two primary types of boiler headers. The boiler’s steam is collected and distributed by the steam headers, while the water or other fluids that enter the boiler are distributed by the feed headers. In order to keep the system secure, efficient, and balanced, both kinds are essential.

The Safety Functions of Boiler Headers

1. Pressure Management

One of the key safety duties of boiler headers is to regulate the pressure within the steam system. Boilers work under high pressure, and unexpected shifts or imbalances can result in deadly circumstances. Because of their sturdy construction and well-planned positioning, boiler headers aid in the system’s uniform distribution of steam pressure. This pressure control system eliminates localised pressure spikes, which can lead to equipment failure or even explosion.

Assuring that the integrity of the steam system is preserved even in the most adverse circumstances, RIBO Industries specialises in producing headers that can tolerate high pressures and temperatures. As a dependable part of pressure management, headers are put through a thorough testing process to ensure they match industry requirements.

2. Thermal Expansion Compensation

Due to the high temperatures involved, steam systems experience severe thermal expansion. Boiler headers are designed to handle this expansion without putting undue strain on the system. Headers offer a sturdy yet flexible channel for steam distribution, preventing pipes and other components from warping or breaking.

The materials used to make RIBO Industries’ headers have superior thermal expansion characteristics. This guarantees that the headers retain the shape and function even when temperatures fluctuate, lowering the likelihood of thermal stress-related failures

3. Condensate Removal

Condensate, or the water created as steam cools, can cause serious difficulties in steam systems if not correctly managed. Accumulated condensate can induce water hammer, a phenomenon in which a sudden surge of water sends a pressure shockwave through the pipework. This presents a major safety risk and has the potential to harm equipment.

Boiler heads are frequently constructed with characteristics that make condensate evacuation easier. By integrating cutting-edge drainage solutions into the headers, RIBO Industries ensures condensate is effectively evacuated from the system, preventing water hammering and preserving safe operation.

4. Efficient Steam Distribution

Safe operation is just as essential as operational efficiency when it comes to efficient steam distribution. Specific system components may experience over-pressurization, while other components may experience under-pressurisation due to uneven steam distribution. This imbalance might result in breakdowns and hazardous conditions.

The ideal steam flow is achieved by the engineering of RIBO Industries’ boiler headers, which guarantee the efficient and uniform distribution of steam throughout the system. By maintaining constant pressure and temperature, this balanced distribution lessens the possibility of operational dangers.

5. System Isolation and Maintenance

Another critical safety function of boiler headers is to isolate and maintain systems. Headers frequently incorporate valves and access points that enable sections of the steam system to be isolated for maintenance or in the case of failure. This functionality is critical for performing repairs safely and effectively without having to turn off the entire system.

With maintenance in mind, RIBO Industries incorporates characteristics that promote simple access and isolation into their header designs. This reduces downtime and operational disruptions while also improving system safety during regular maintenance.

The Expertise of RIBO Industries

Combining state-of-the-art technology with decades of experience, RIBO Industries is at the forefront of the boiler header manufacturing industry. In order to make boiler headers safer for steam systems, RIBO Industries does the following:

1. Advanced Materials and Manufacturing Techniques

Modern materials used by RIBO Industries provide exceptional strength and resistance to high temperatures and pressures. Advanced production processes guarantee that every header is constructed to exacting standards and is resilient enough to withstand the demands of industrial use.

2. Rigorous Testing and Quality Assurance

Every boiler header manufactured by RIBO Industries goes through thorough testing to ensure that it meets or exceeds industry standards. To guarantee that every header operates dependably in practical settings, this involves temperature cycling, pressure testing, and inspections.

3. Custom Solutions for Unique Requirements

Given that each steam system is different and has requirements that must be met, RIBO Industries provides specialised solutions. This unique technique ensures that its headers integrate easily into any system, resulting in optimal performance and safety.

4. Continual Innovation

In an effort to enhance the effectiveness and safety of their goods, RIBO Industries is dedicated to ongoing innovation. By being on the bleeding edge of technology and industry changes, they ensure that their boiler headers remain the best choice for steam systems around the world.

Conclusion

Boiler headers are essential parts for steam systems’ efficiency and safety. In order to ensure safe and dependable operations, function in pressure management, thermal expansion compensation, condensate removal, effective steam distribution, and system isolation is essential. With a focus on safety, dependability, and innovation, RIBO Industries is a trusted partner for businesses looking to optimise their steam systems and assure the highest levels of operational safety.