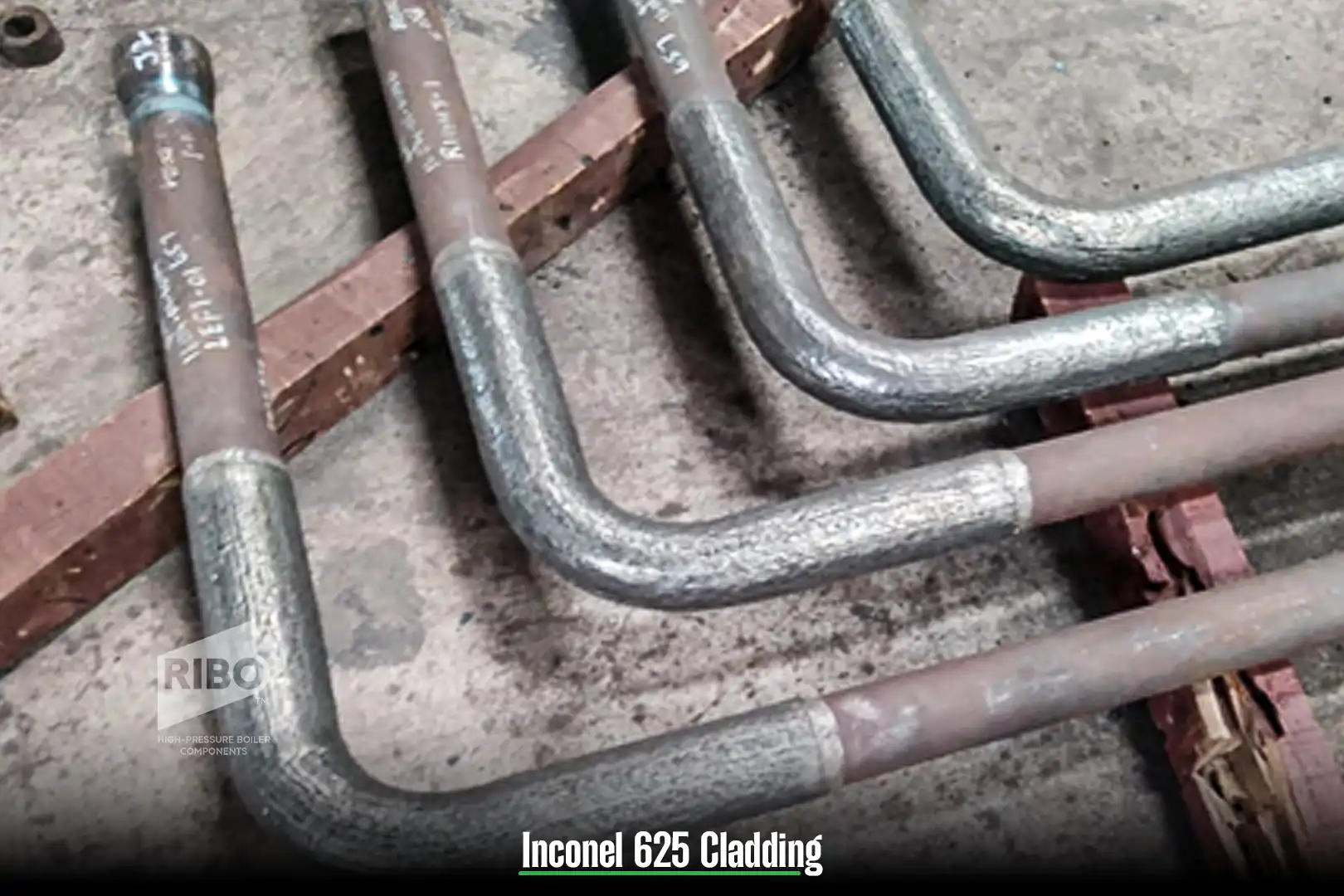

Inconel 625 Cladded Boiler Components

RIBO Industries, a leading manufacturer and supplier of advanced boiler components, delivers Inconel 625 cladded solutions engineered to withstand the harshest industrial conditions. With precision cladding technology and uncompromising quality standards, our components ensure superior resistance to corrosion, oxidation, and high-temperature environments. Trusted by power plants and heavy industries worldwide, we combine technical expertise with reliable supply to meet diverse operational demands.

Engineered for Extreme Performance in Demanding Environments

RIBO Industries offers precision-engineered Inconel 625 cladded boiler components such as :

- Inconel 625 Cladded Waterwall Panels

Protects furnace walls from corrosive combustion gases and thermal fatigue. Inconel 625 cladding ensures long-term integrity even under cyclic thermal loads. - Inconel 625 Cladded Economisers

Enhances heat recovery while resisting acid dew-point corrosion. Ideal for high-sulfur fuel applications and waste heat recovery systems. - Inconel 625 Cladded Superheaters Coils

Maintains metallurgical stability at elevated temperatures. Inconel 625 cladding prevents oxidation and stress corrosion cracking in steam circuits. - Evaporators Coils

Delivers consistent performance in high-pressure steam generation. Cladding resists pitting and crevice corrosion, extending service life.a

Applications use of Inconel 625 Cladded Boiler components :

Inconel Cladded Boiler components are ideally recommended for

- Thermal power plants

- Waste-to-energy facilities

- Petrochemical refineries

- Biomass and industrial boilers

Benefits of Inconel 625 Cladded Boiler components:

Environment Friendly

Supports circular economy/environmental goals by reducing replacement scrap and promoting boiler component reuse

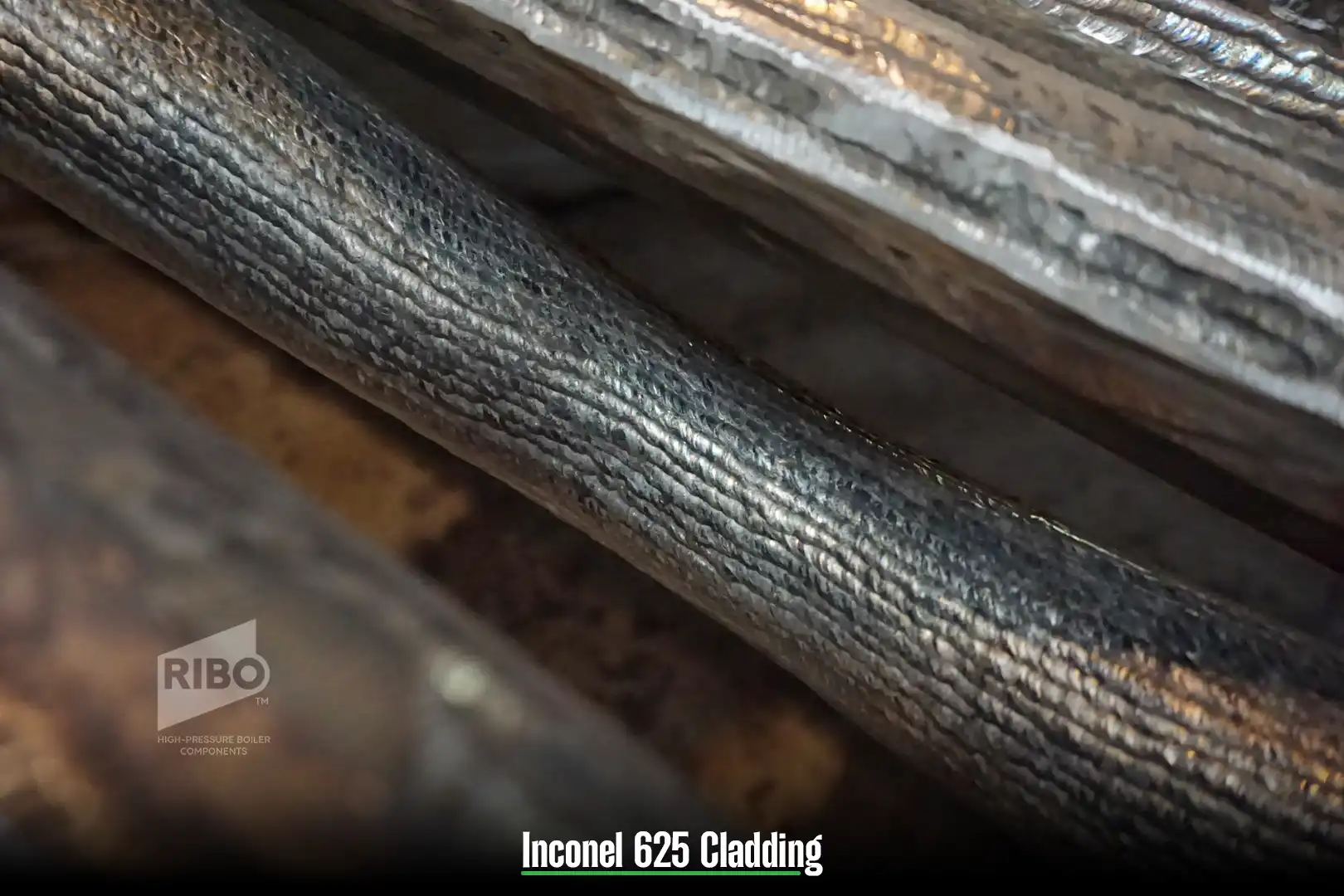

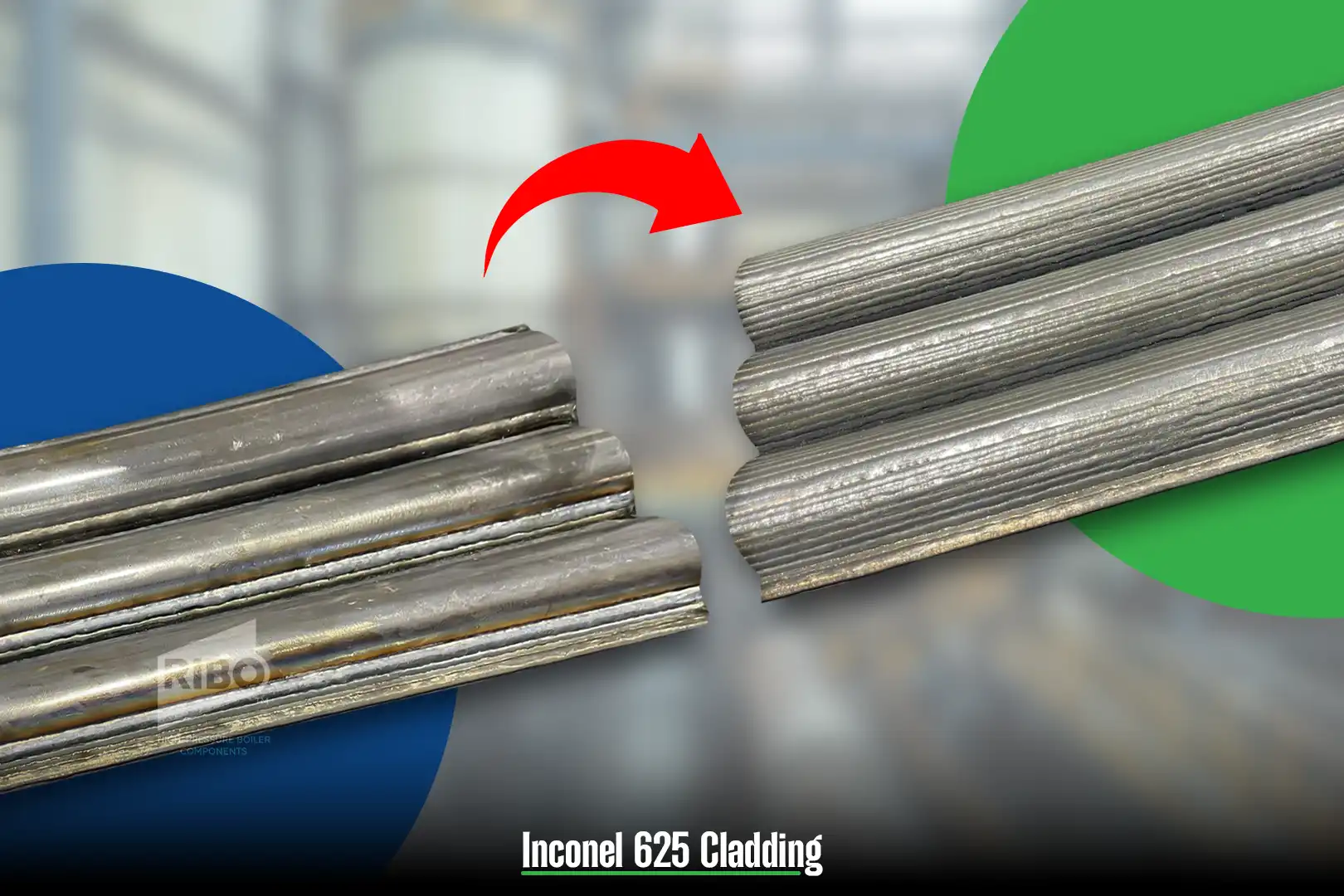

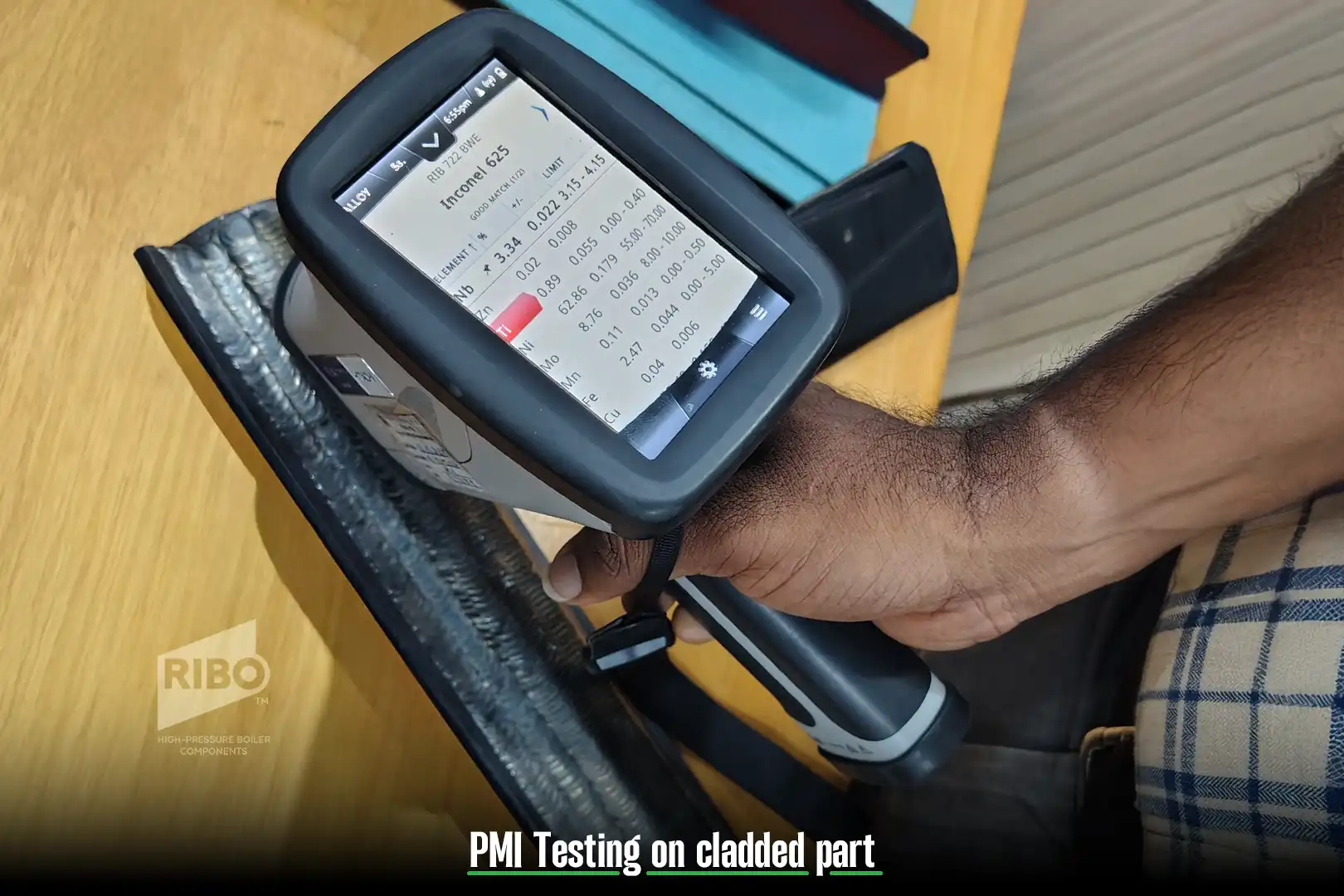

Most Reliable Process

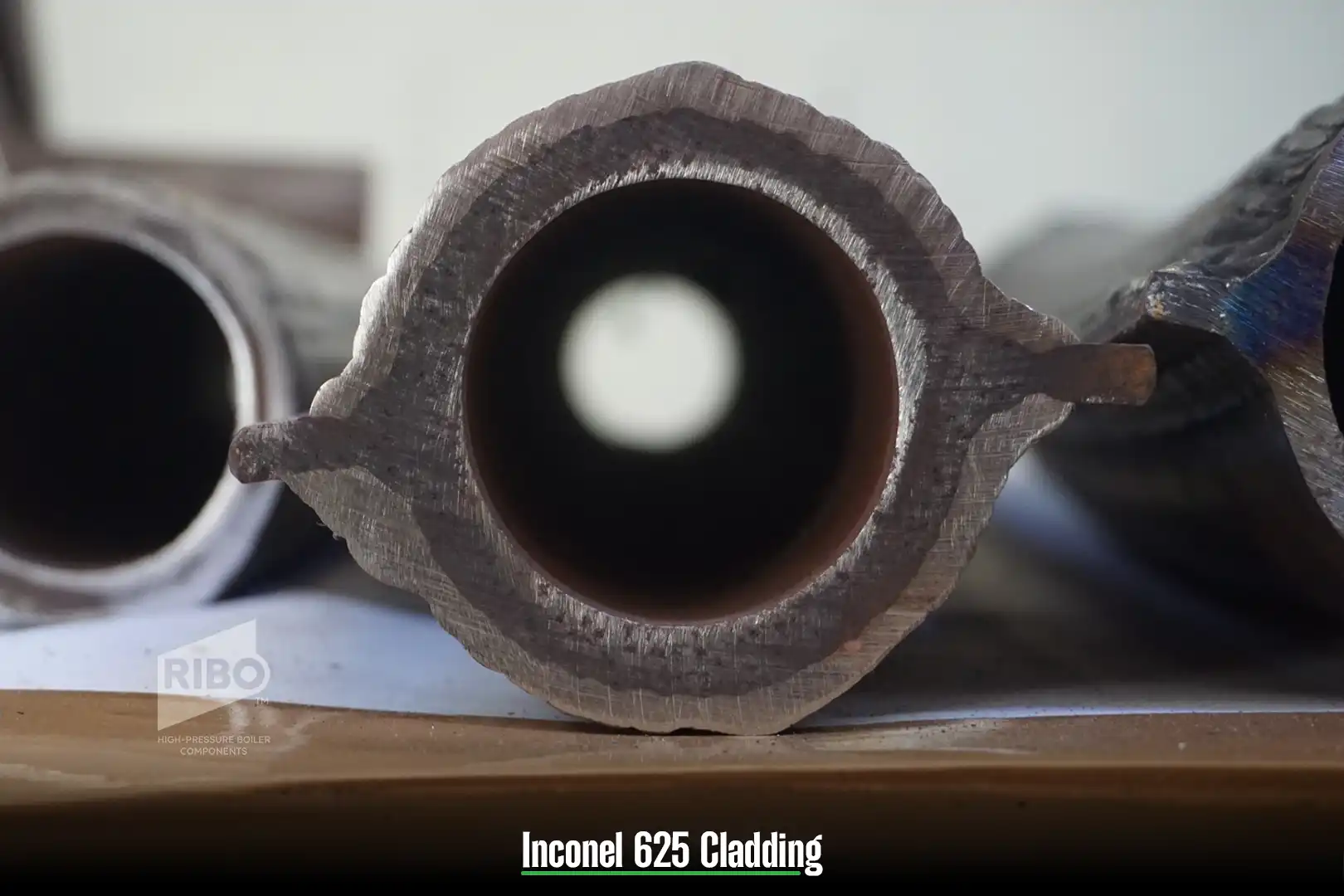

We employ Weld overlay technology with seamless integration with base materials for enhanced bonding resulting in High tensile strength withstanding thermal cycling and mechanical stress

Extended Boiler Life

As Inconel 625 is an Nickel-based alloy. It delivers Exceptional resistance to oxidation, carburization, and chloride attack. Avoids unexpected failures arising out of these factors

At RIBO, we offer a variety of designs and combinations to meet the individual requirements of each boiler system. Factors such as tube number and arrangement, finned tubes to increase heat transfer surface area, and material selection based on pressure, temperature, and flue gas composition are all considered to provide the optimal solution.

Partner with Us

We support custom specifications, fast turnaround, and full documentation for quality assurance. Let’s help you future-proof your boiler systems.

If you are looking for more information or clarification, just fill in the form and our team representative will get in touch. You can also chat with us on whatsapp, by simply scanning the QR code below or call +91 94421 42112

Your Information is secure with us.

we do not share or sell contact information

Corporate Office

RIBO Industries Private Limited

PO Box No.101, Cantonment, Trichy 620001, Tamilnadu, INDIA.

+91 944 214 2112 | enquiry@ribo.in | +91431 – 2402112

Quick Links

ASME (S) (U) | ISO 9001 | ISO 14001 | ISO 45001